€565.00*

Free shipping

Available in 7 days, delivery time 1-3 days

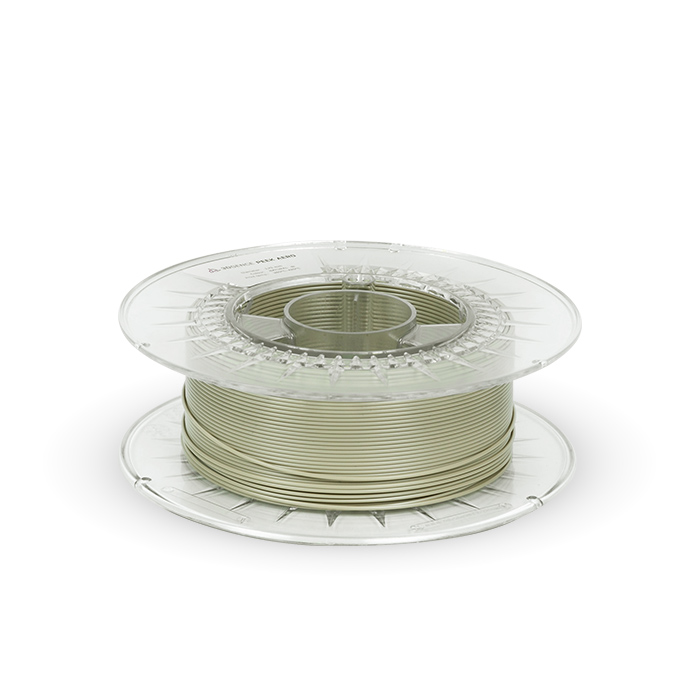

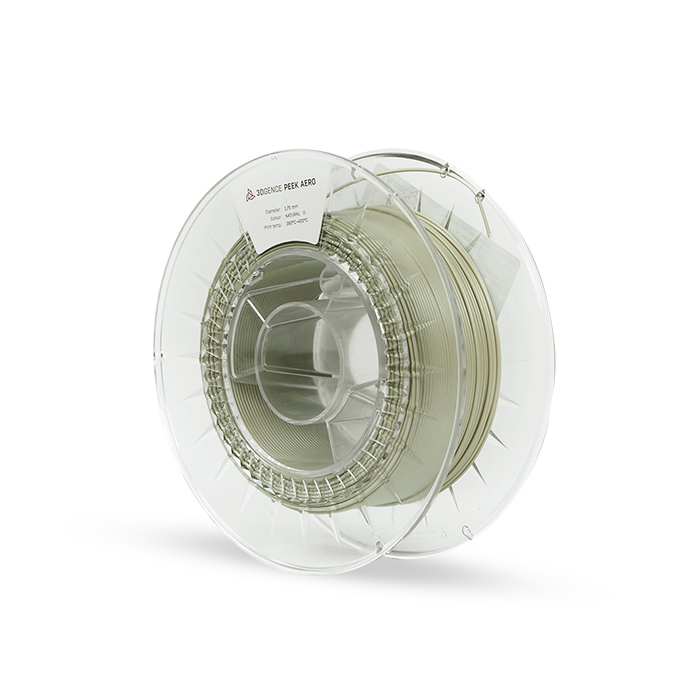

PEEK™ Aero from 3DGence is one of the highest performing thermoplastics available for available for additive manufacturing. A key feature of the polymer is its compliance with AS9100 certification for aerospace applications.

Description of the PEEK™ Aero Filament

Certified filaments play a key role in industrial industrial 3D printing, especially in these areas where safety is paramount. is paramount. PEEK™ Aero belongs to the group of high-performance polymers - filaments that can withstand the most demanding environments. It characterized by the highest heat resistance (high-temperature applications up to 260 °C), chemical resistance, high tensile strength and excellent impact resistance. impact resistance. Thanks to its flame retardancy (UL94 V-0), its low weight and the weight and AS9100 Aerospace certification, the material is used in the aerospace and the aerospace and defense industries.

The most important advantages of PEEK AERO

- The most important advantages of PEEK™ Aero certified according to AS9100,

- Excellent heat resistance: High temperature applications up to 260°C,

- high chemical resistance and tensile strength.

PEEK™ Aero industrial application in 3D printing

Due to its properties and certifications PEEK™ Aero can be used for end parts in the aerospace and defense sectors. defense sector can be used. Some customers print machine and equipment parts with PEEK™ Aero, others find it useful for sliding and sliding applications. Due to its high heat resistance (up to 260 °C), it is a suitable it is a suitable filament for prints exposed to extreme temperatures. are exposed to.

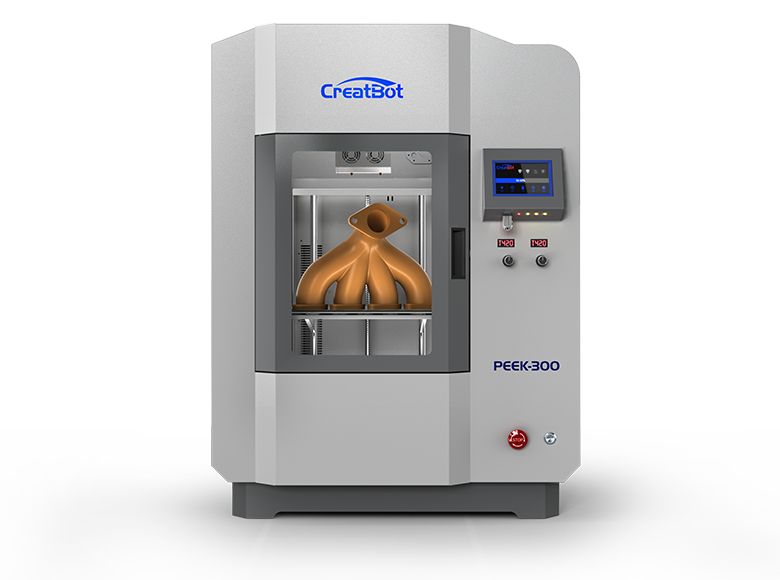

PEEK™ Aero: Good to know

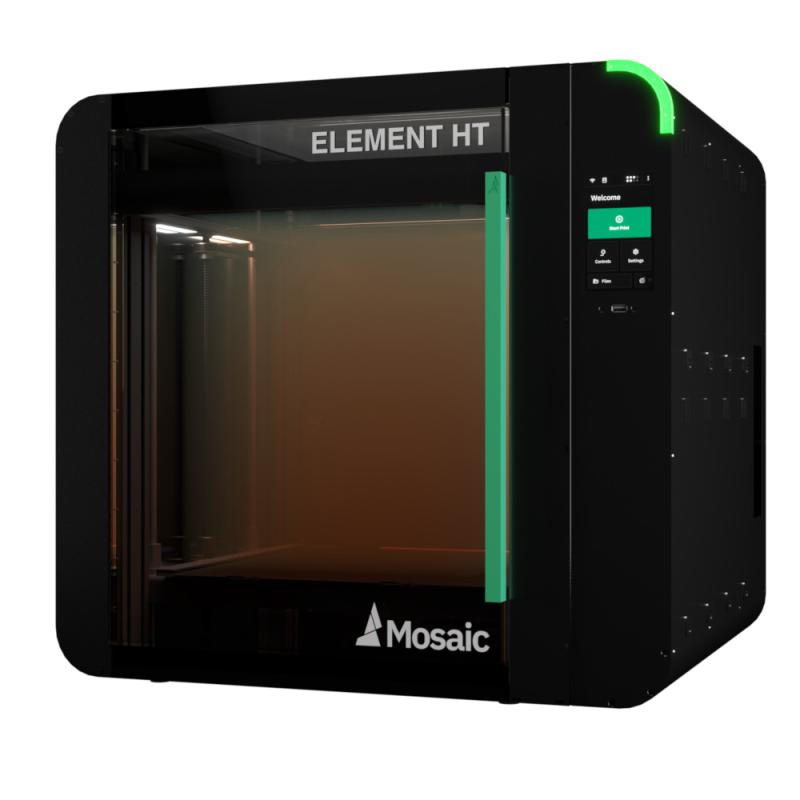

3D printing with PEEK™ Aero delivers exceptional, durable results, but requires professional equipment to achieve the best achieve the best results. With our INDUSTRY™ F421, which offers high-speed printing and a large chamber volume, you can take advantage of all the possibilities of additive manufacturing with PEEK™ Aero. It is available with the compatible with the soluble support material ESM-10.

Login