Price on request

Free shipping

Available in 7 days, delivery time 8 - 9 Wochen

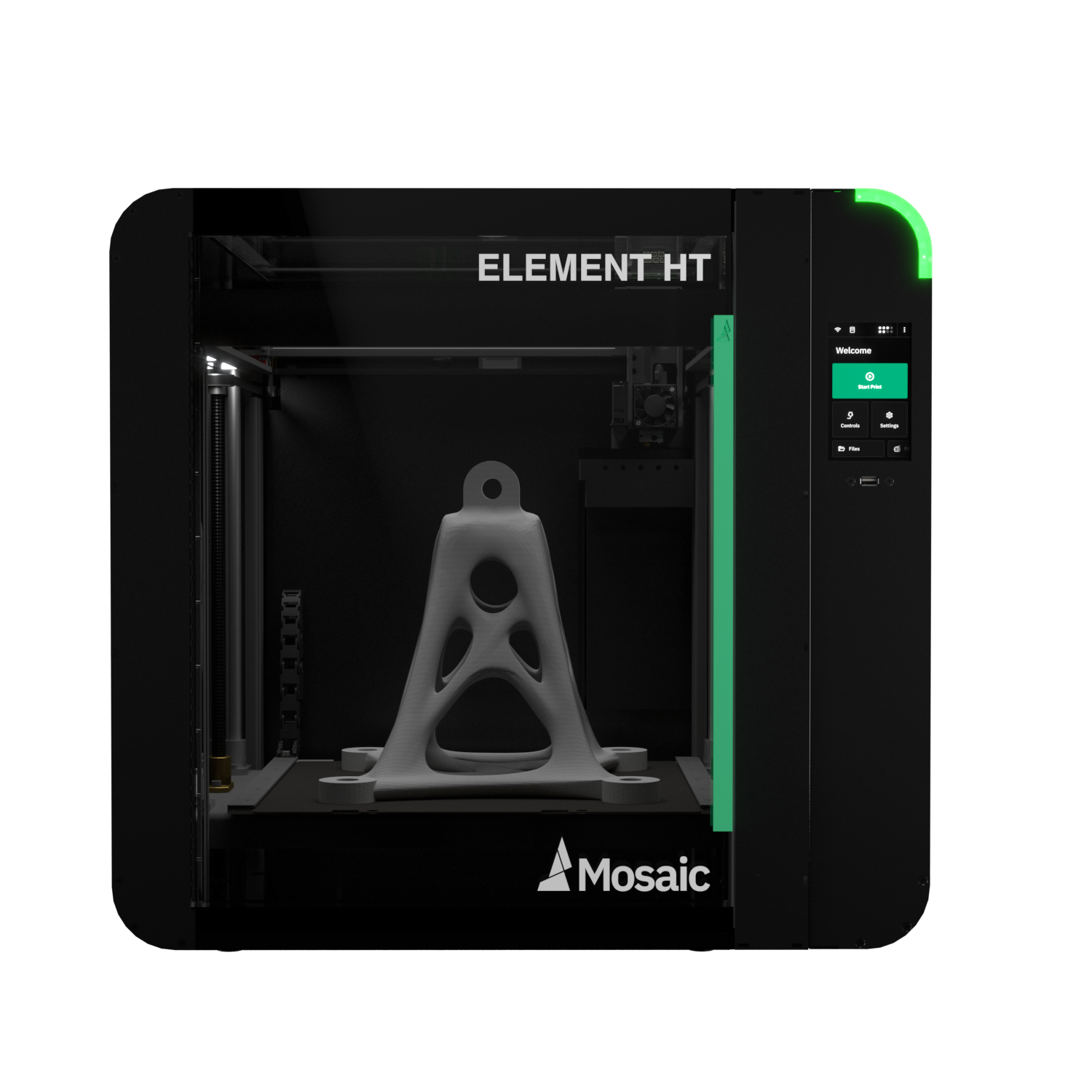

Mosaic Manufacturing Array XT 3D print farm

Array XT offers all the features and benefits of Array, but also offers the ability to print technical materials at high temperatures. temperatures. This is achieved by ends that are heated to 500 °C, and chambers that are actively heated to 90 °C.

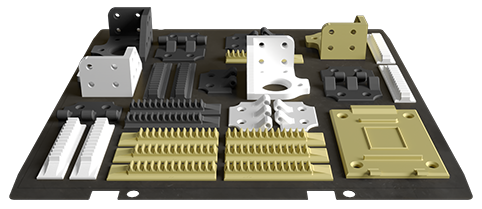

With the large build volume of the Array XT, the intelligent pressure queue, the automatic pressure monitoring and the modular design we can now achieve high machine utilization, low downtimes and high throughput in high throughput in 3D printing.

Implementing Array into your production system means you spend less time maintaining and managing your printers and more time printing. and have more time to print - even when you're not on site. on site.

Array's robotic gantry system changes materials and print beds to materials and print beds to ensure your printers are up and running around the clock. are in operation around the clock.

By increasing your printing capacity, Array ensures lower cost per part, reduces labor and guarantees a shorter payback period shorter payback time than other industrial printing systems.

Benefits and features of Array XT:

- Four automated 3D printers

- One robotic gantry system to control the entire system

- One storage cart for storing the finished parts

- A Construction volume of 355 x 355 x 355 mm (per printer)

- The CANVAS-capable intelligent print queue

- Internal webcams to monitor prints and detect errors in real time real time

- A modular design for easy maintenance options

- At least 72 hours of operation without operator intervention

An automated multi-material 3D printing system:

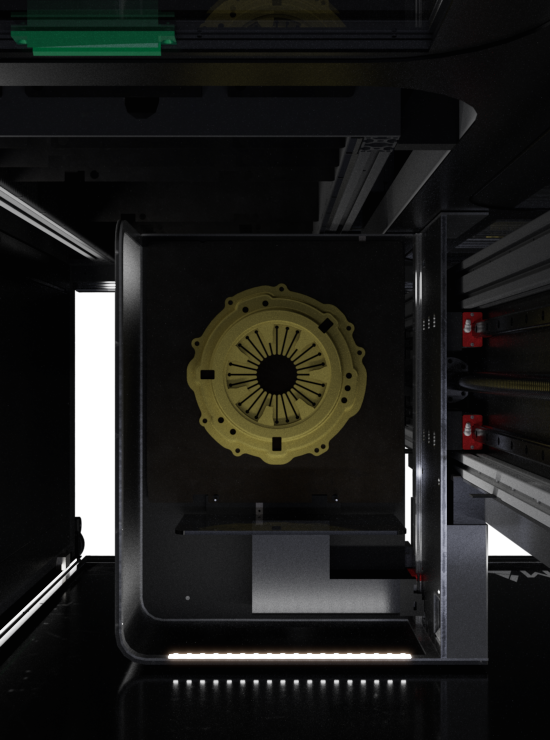

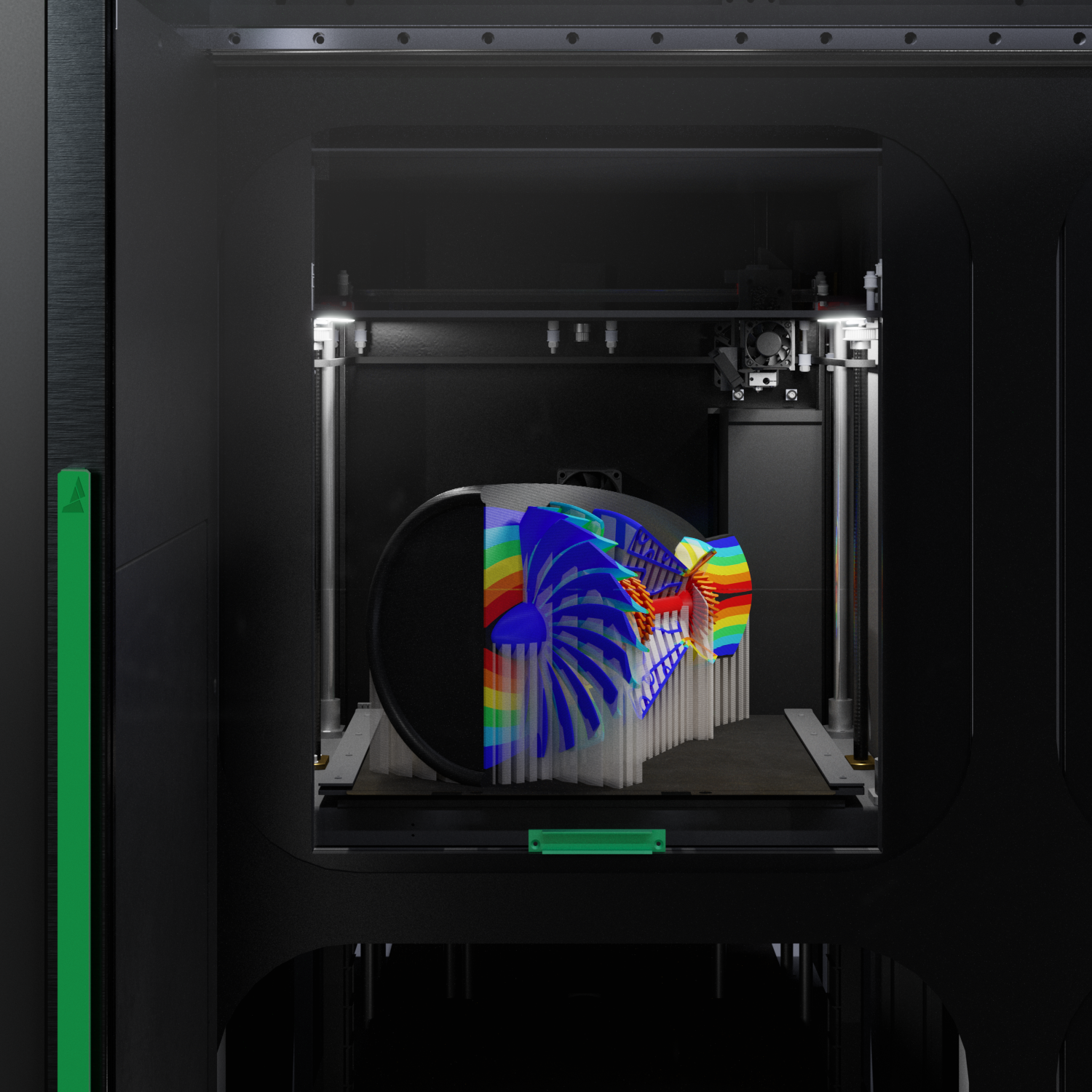

Each printer within Array XT is equipped with Mosaic Palette X technology and can print models in up to eight materials and/or and/or colors. The new CANVAS Array Slicer software, which has been specially developed specifically for working with Array, allows you to:

- The Create an intelligent print queue that allows Array XT to continue to continue printing autonomously for at least 72 hours.

- The seamless management of all your projects, alone or in a team.

- The assignment of access rights to team members (e.g. owner, administrator, operator).

- The remote monitoring of your prints by connecting to the webcams within within Array XT.

Once printing is complete, the automated gantry system removes the gantry system removes the bed with the finished part from the printer, places it in the the storage cart, places a new bed in the printer, and the intelligent CANVAS' intelligent queue management starts the next print. This process continues until the storage cart is filled with finished parts. is filled. Once it is full, an operator replaces the storage cart with a new one a new one with fresh beds and the Array XT process starts again.

.jpg)

Main advantages of Mosaic Manufacturing Array XT:

- Multi-material 3D printing: All four printers (Element HT) within Array XT are capable of printing in up to eight materials and colors, but all four can also print completely print completely different parts at the same time.

- High automation: When your prints are ready, they are automatically saved for you saved for you until your shopping cart is filled with finished parts.

- High material loading capacity: Each printer in the array can hold 16 kg of material so you have a total of 64 kg of material on deck, ready to print at ready for printing at any time.

- Robotics: The array robot removes the finished prints with their bed, stores them and places a new bed in the printer to start the next print. start the next print.

Material compatibility:

Array is compatible with most common materials. These include nylon / nylon CF, ABS, PLA, PETG, TPU, PVA and HIPS. In addition Array XT also supports high-temperature materials such as PEEK, PEKK, PPSU or Ultem 9085.

Difference between Array and Array XT:

The two 3D print farms from Mosaic Manufacturing, Array and Array XT, are based on the Element and Element HT technologies. The difference is that the Element HT also has a build chamber heater. installation space heating. With a heated installation space, more materials such as materials such as PEEK or PEKK can be processed. The maximum nozzle temperature is also higher with the Element HT (or Array XT) than with the normal element (or array).

Videos

.png)

Login