€11,303.81*

Free shipping

Available, delivery time: 1-2 weeks

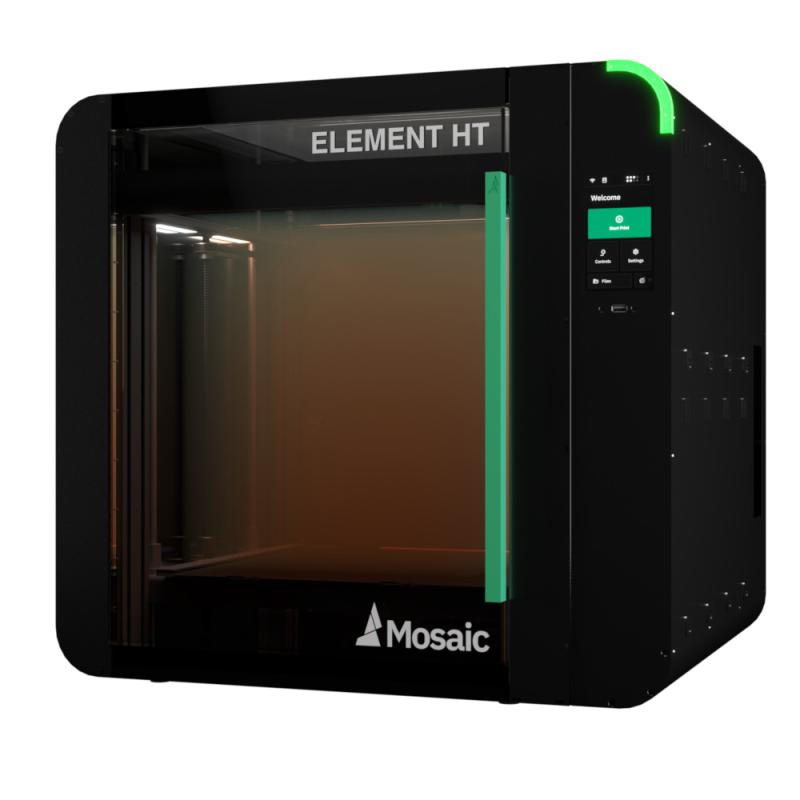

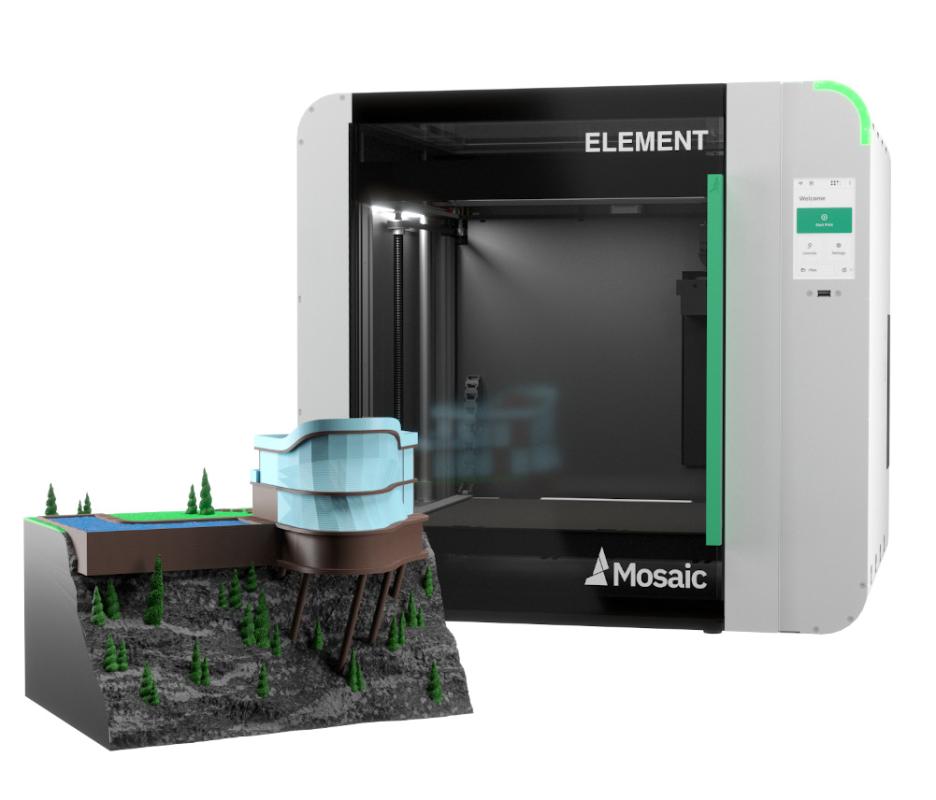

Mosaic Element HT High Temperature Multi-Material 3D Printer

The Element HT 3D printer from Mosaic Manufacturing, offers all the benefits of the Element with the added ability to process high temperature materials. Thanks to the multi-material 3D printing system, you can use up to 8 different materials and colors in one printing process, significantly improving efficiency. In combination with the intelligent CANVAS Slicer software and the Mosaic Material Pods, the Element 3D printer automates the entire process. You are able to produce complex parts with high-temperature filaments with unmatched simplicity.

The most important features at a glance

✔ Modular print head - Kinematically coupled

✔ Nozzle up to 500°C and print bed up to 120°C

✔ Heated pressure chamber up to 90°C

✔ Cloud system

✔ HIWIN linear rails

✔ Pressure volume of 350 x 350 x 350 mm

✔ Flexible printing plate

✔ Trinamic stepper motor driver

✔ Core XY kinematic system

✔ LED print status display

✔ Can process up to 8 materials during one printing process

✔ 2-year manufacturer's warranty

Compatible & Available Printing Materials

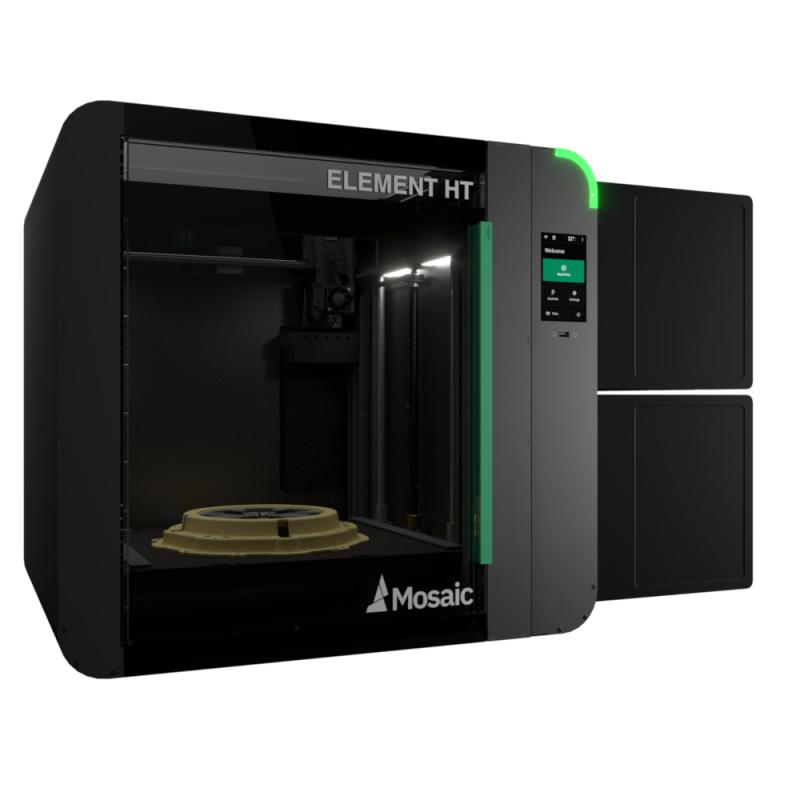

By using Mosaic's own materials in conjunction with the material pods, the Element HT 3D printer enables automated filament management while ensuring long-lasting reusability.

Currently available original Mosaic filaments:

Nylon and CF Nylon

ABS

PLA

PETG

TPU

PVA

HIPS

PEEK

PEKK

Ultem 9085

Element is an open printing system, you can always use third-party filament.

Explanation of Multi-Material Management & Automated Workflows

Each of the material pods contains its own motor that transports the filament from the pod to pallet X and on to the print head. Unlike the Palette devices, Palette X does not splice the materials. The reason for this is that when using multiple combinations of different material types, splicing becomes less reliable. Together with Palette X, Element has full control over material management and can therefore dispense with splicing.

This results in higher print quality and less wasted material.

Element is also linked to CANVAS. This means that creating, editing, organizing and cutting your multi-material models and sending them to the printer is extremely easy. The entire process is completed in a matter of minutes.

Special features

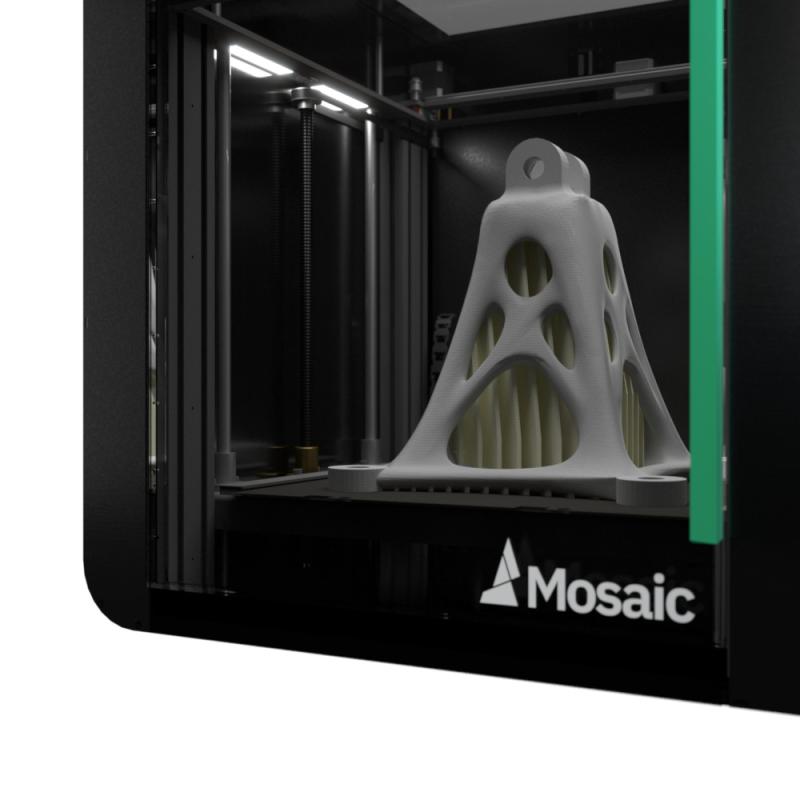

Print volume

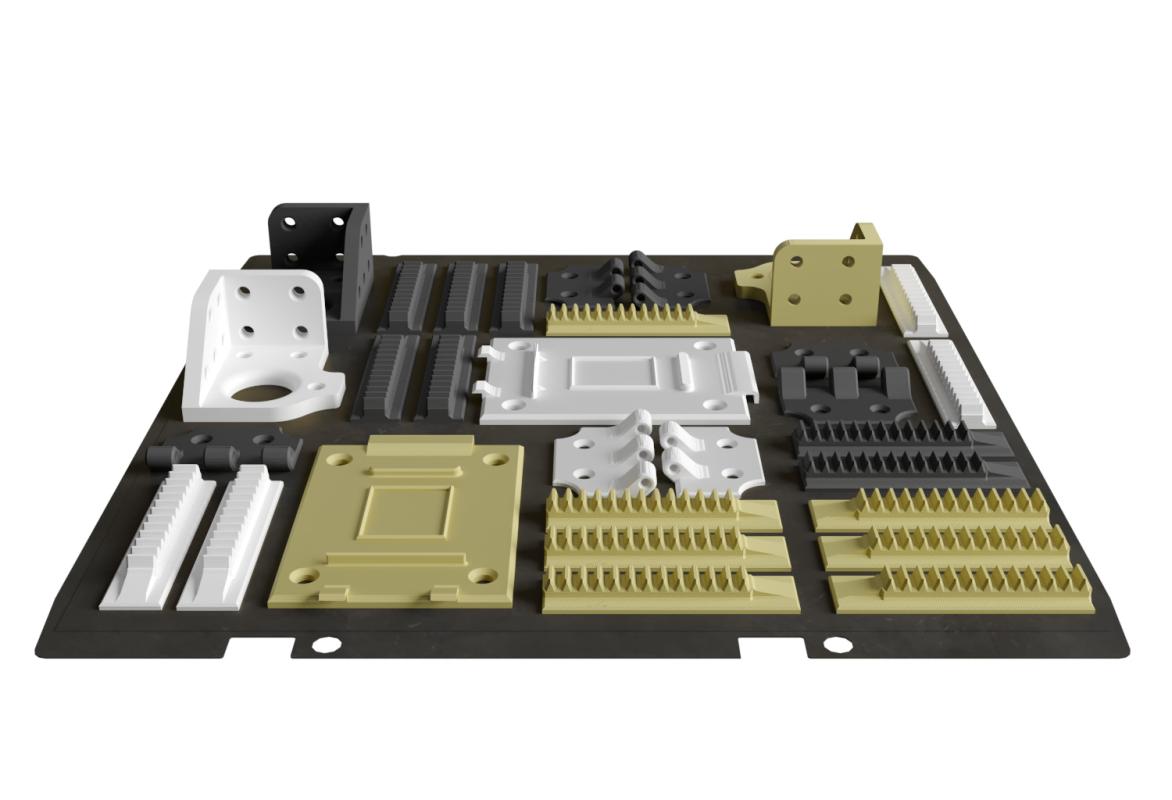

Due to the large print volume of 350 x 350 x 350 mm, you can significantly increase your productivity and print large objects from up to 8 different colors.

Flexible use

Element optimizes the printing process by simultaneously printing support structures while you finish your piece(s) in any number of materials.

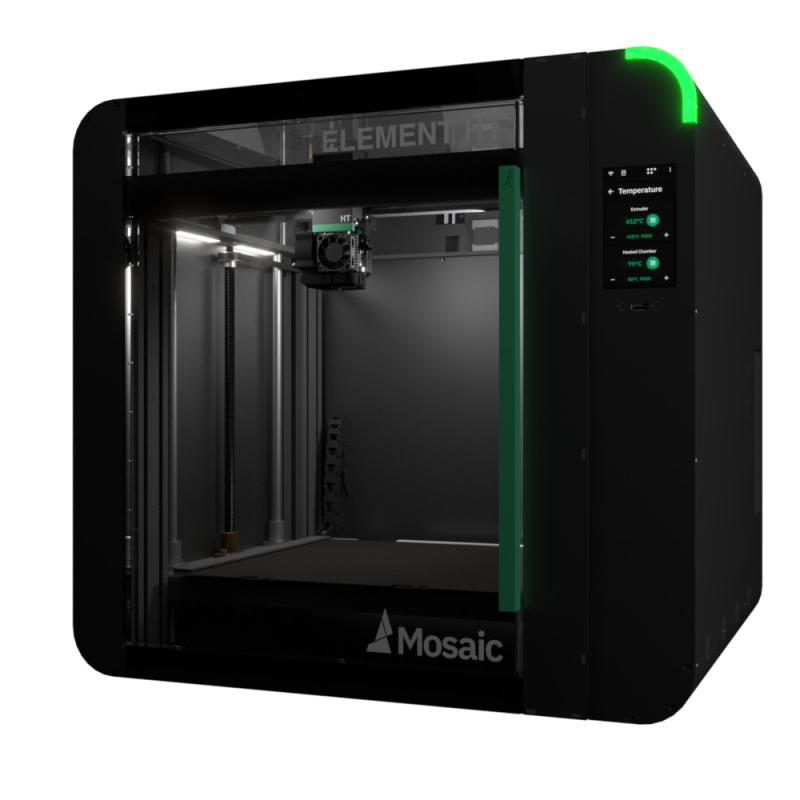

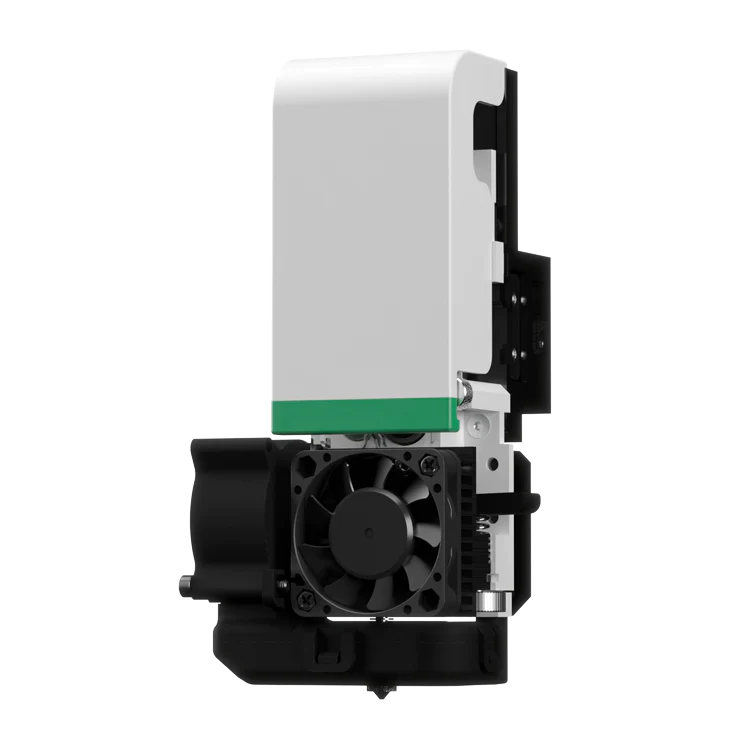

Modular extruder

Modular design makes it easier than ever to remove and reinstall the printhead for repairs or replacement.

Heated pressure chamber

Element HT features an actively heated chamber up to 90 °C. The heated pressure chamber supports the pressure process of materials such as PEEK, PEKK and Ultem 9085.

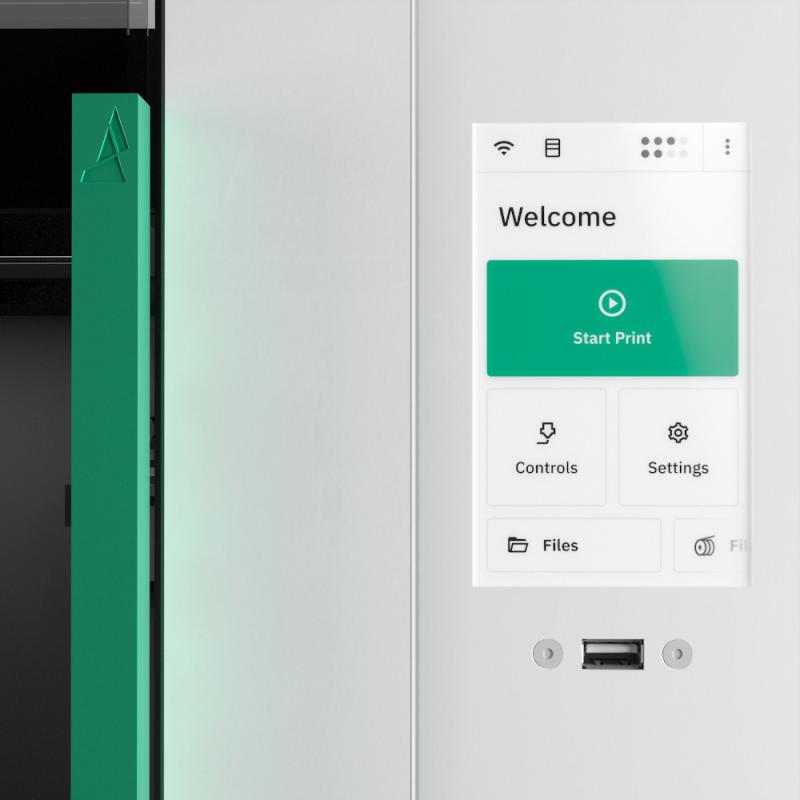

CANVAS Cloud - Free single user license included

CANVAS is Mosaic's simple and easy-to-use slicing software. CANVAS is free for single users. CANVAS TEAMS will be available to a larger number of employees, enabling effective collaboration.

Set access rights for all team members, from owner to user.

Apply color, logos, serial numbers and more directly to your 3D models from a file using CANVAS digital.

Share, store, organize and track your print settings in the cloud for yourself or for the team.

Conveniently monitor your print operations via webcam from home or anywhere else.

How do you differentiate the Element and Element HT 3D printers ?

From a design standpoint, the Element and Element HT 3D printers from Mosaic are almost identical. The only differences are that the Element HT has a heated print chamber (up to 80°C) and an elevated nozzle temperature of up to 500°C. This makes it possible to print high-performance materials such as PEEK or Ultem with the Element HT.

Videos

| Additional Features: | Multi-material 3D printing, Pressure chamber up to 90°C |

|---|---|

| Ausführung: | Desktop 3D-Drucker, Industrie 3D-Drucker, PEEK 3D-Drucker |

| Extruder: | Dual extruder |

| Features: | Air filter, Automatic calibration, Filament RunOut Sensor, Heated pressure plate, Integrated camera, Network-compatible, Open filament system |

| Field of application: | Components with high surface quality, Industry, Private use, Production of stable components, Production of temperature-resistant components, Prototype production, Small series production, Training/education |

| Installation space: | > 30 cm, 0-20 cm, 21-30 cm |

| Material: | ABS, ABS-ESD, ASA, BVOH, CPE, Carbon, HIPS, NYLON, PC, PET, PET-G, PLA, PP, PVA, TPC, TPE, TPU |

| Printer properties: | Nozzle up to 500°C |

| Print volume: | Installation space: 350x350x350mm |

| Properties: | Closed pressure chamber, Heated pressure plate |

| Technology: | FDM/FFF (Fused Filament Fabrication) |

Login