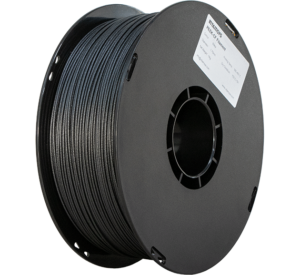

€259.00*

Available in 7 days, delivery time 1-3 days

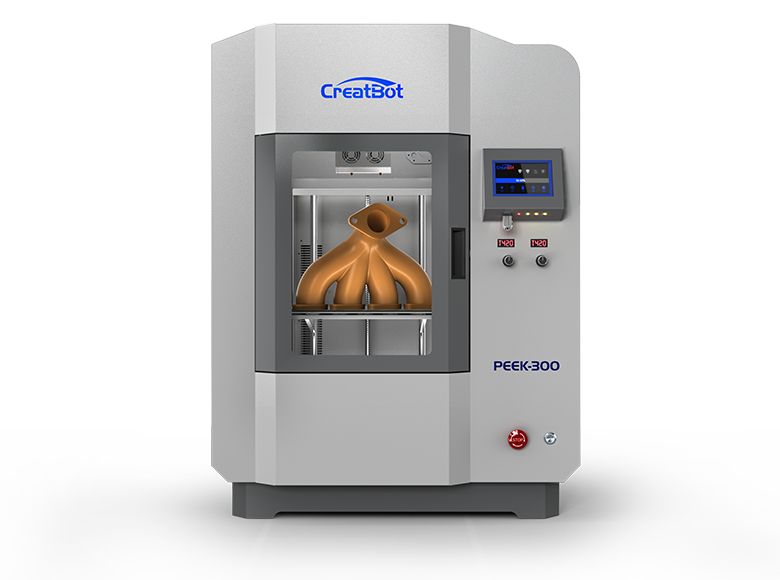

3DGence PEEK Natural Filament

PEEK has exceptional mechanical and thermal properties thermal properties and high chemical resistance. This material combines excellent sliding properties, mechanical strength and resistance to high resistance to high temperatures, which makes it ideal for the production of functional for the manufacture of functional machine components and devices.

Pressure recommendations:

Before each use, PEEK should be preheated to 75°C for about 24 hours. for about 24 hours. For this you can use the build chamber of the 3D printer or a use a special dryer. Even a small amount of moisture in the material material negatively affects the mechanical properties and quality of the printed model, as air bubbles can appear on the walls.

When designing models, it is important to ensure that the minimum cross-section in the model should not be less than 25 mm². The minimum wall thickness during printing without losing strength is 2 mm. It is It is possible to print thinner walls, but they have considerably reduced mechanical mechanical strength.

PEEK can be used in conjunction with the soluble support material 3DGence ESM-10 can be used. The properties of ESM-10 ensure the stability of the stability of the support structure when printing takes place in a heated chamber where the internal temperature can exceed 80 °C.

Applications:

Parts for machines and systems Interior fittings for Aircraft interiors Automotive industry Medical applications

Mechanical properties

Tensile strength: 105 MPa

Young's modulus: 4.1 GPa

Flexural modulus: 3.9 GPa

Charpy: 14 kJ/m2

Extension: 30%

3D printing conditions on 3DGence devices

Extrusion: 360 - 400°C

Recomm. Heating bed temperature: 120°C

3DGence Certified Material Base: Yes

Login