€122.87*

Available in 7 days, delivery time 1-2 weeks

Mosaic Matrix (CF Nylon-6): Das Filament für höchste Ansprüche

Suchen Sie nach einem Filament, das kompromisslose Festigkeit, Wärmebeständigkeit und Leichtbau vereint? Dann ist Mosaic Matrix (CF Nylon-6) die perfekte Wahl für Sie! Dieses innovative Material überzeugt durch seine herausragenden Eigenschaften:

- Beeindruckende Festigkeit: Mit einer Zugfestigkeit von 63 MPa und einem Elastizitätsmodul von 3800 MPa übertrifft Mosaic Matrix (CF Nylon-6) viele Standardfilamente deutlich.

- Hohe Wärmebeständigkeit: Das Material behält seine Form bis zu 145 °C und ist somit ideal für Anwendungen in heißen Umgebungen.

- Exzellentes Verhältnis von Festigkeit zu Gewicht: Mosaic Matrix (CF Nylon-6) ist extrem leicht und gleichzeitig enorm stabil. Dies macht es zum perfekten Material für gewichtssensitive Anwendungen.

Anwendungsbereiche:

- Luft- und Raumfahrt: Dank seiner hohen Festigkeit und Wärmebeständigkeit ist Mosaic Matrix (CF Nylon-6) ideal für die Herstellung von Flugzeugteilen, Raketenkomponenten und Satellitentechnik.

- Automobilindustrie: Das Material eignet sich hervorragend für die Produktion von Leichtbauteilen im Automobilbau, wie z. B. Karosserieteilen, Motorabdeckungen und Fahrwerkskomponenten.

- Schutzhüllen: Mosaic Matrix (CF Nylon-6) bietet robusten Schutz für empfindliche Geräte und Elektronik in rauen Umgebungen.

Setzen Sie auf Mosaic Matrix (CF Nylon-6) und profitieren Sie von:

- Höherer Leistung: Verbessern Sie die Leistung Ihrer 3D-Drucke mit diesem Filament der Extraklasse.

- Zuverlässigkeit: Verlassen Sie sich auf die Langlebigkeit und Robustheit von Mosaic Matrix (CF Nylon-6).

- Vielseitigkeit: Nutzen Sie dieses vielseitige Material für eine Vielzahl von anspruchsvollen Anwendungen.

Entfesseln Sie Ihr Potenzial mit Mosaic Matrix (CF Nylon-6) und erleben Sie 3D-Druck auf höchstem Niveau!

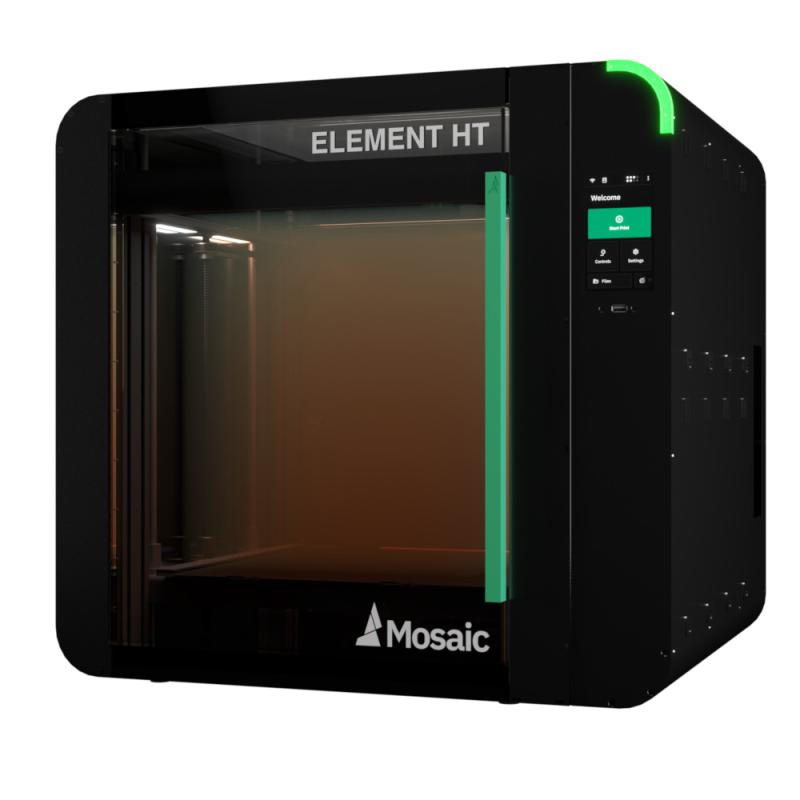

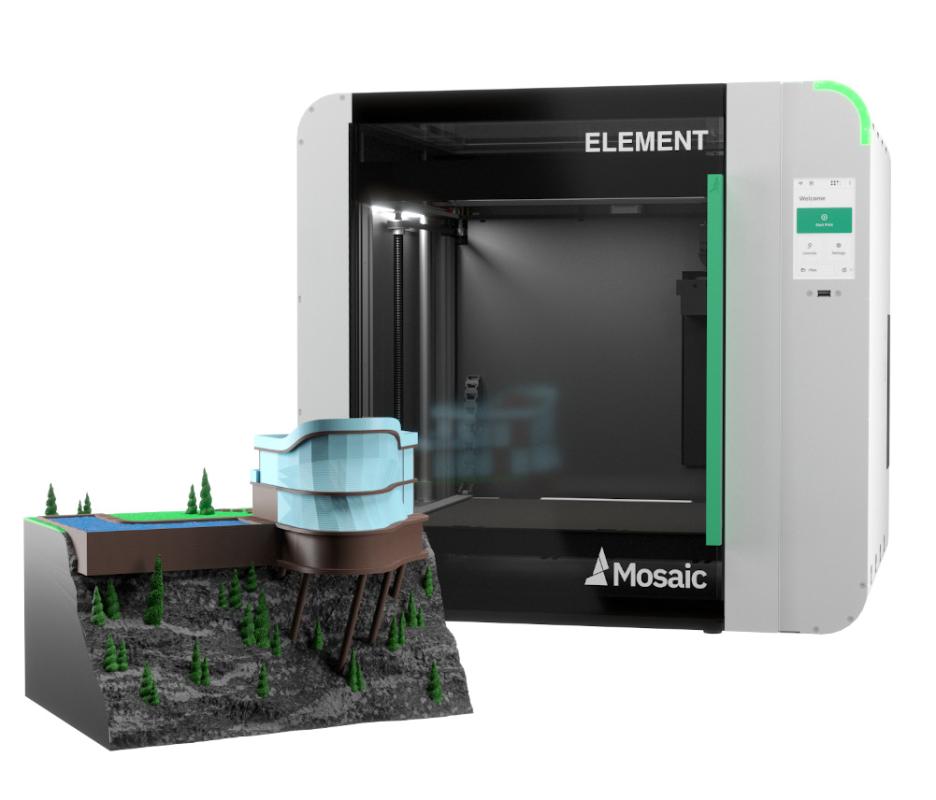

Kompatibel mit: Array, Element, Element HT

Login