Darum sind Schulungen im Bereich 3D-Druck wichtig?

Egal, ob Sie gerade erst in die Welt des 3D-Drucks eintauchen und Unterstützung bei der Erstinstallation benötigen oder bereits Erfahrung haben und nach Optimierungsmöglichkeiten suchen – Schulungen sind entscheidend, um das volle Potenzial des 3D-Drucks auszuschöpfen.

Selbst wenn Sie bereits Erfahrung im 3D-Druck haben, können Schulungen dabei helfen, mögliche Optimierungen zu identifizieren. Der Technologiebereich entwickelt sich ständig weiter, und aktuelles Wissen über die neuesten Entwicklungen und Techniken ist entscheidend, um qualitativ hochwertige Ergebnisse zu erzielen.

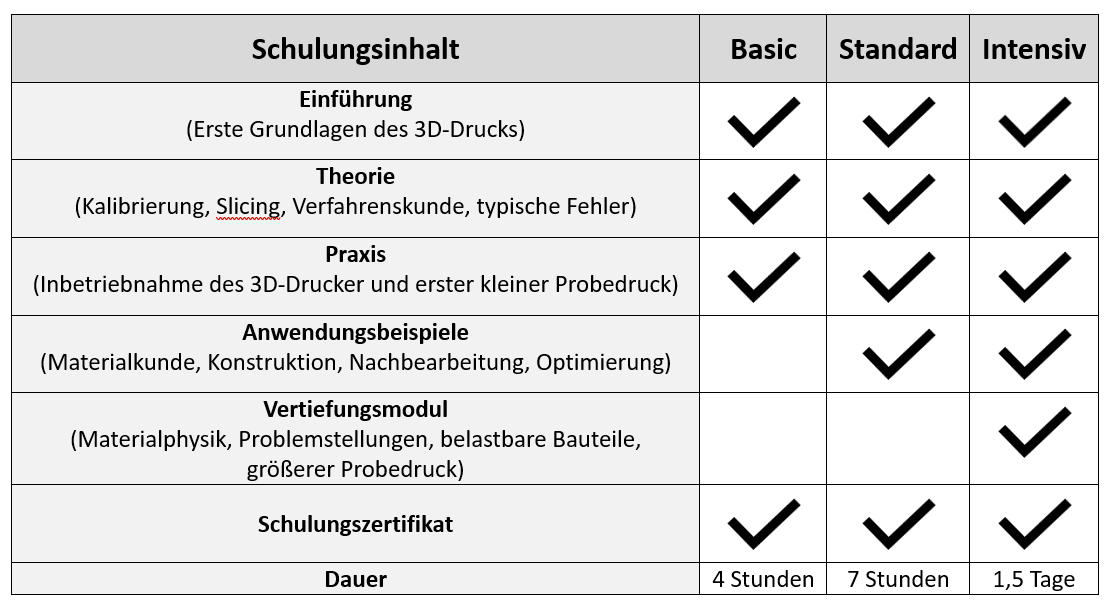

Für erfahrene Anwender, bei denen wiederholt Probleme bei bestimmten Arbeitsschritten, Modellen oder Materialien auftreten, bieten wir maßgeschneiderte Schulungspakete an. Unsere Expert*innen analysieren Ihre spezifischen Herausforderungen und vermitteln Ihnen das nötige Know-how, um diese zu überwinden.

Investieren Sie in Ihr Wissen und Ihre Fähigkeiten im Bereich 3D-Druck – unsere individuellen Schulungspakete sind darauf ausgerichtet, Ihre Bedürfnisse zu erfüllen und Ihnen dabei zu helfen, das Beste aus Ihrer 3D-Druck-Erfahrung herauszuholen.

Gründe für eine Schulung bei BFI 3D

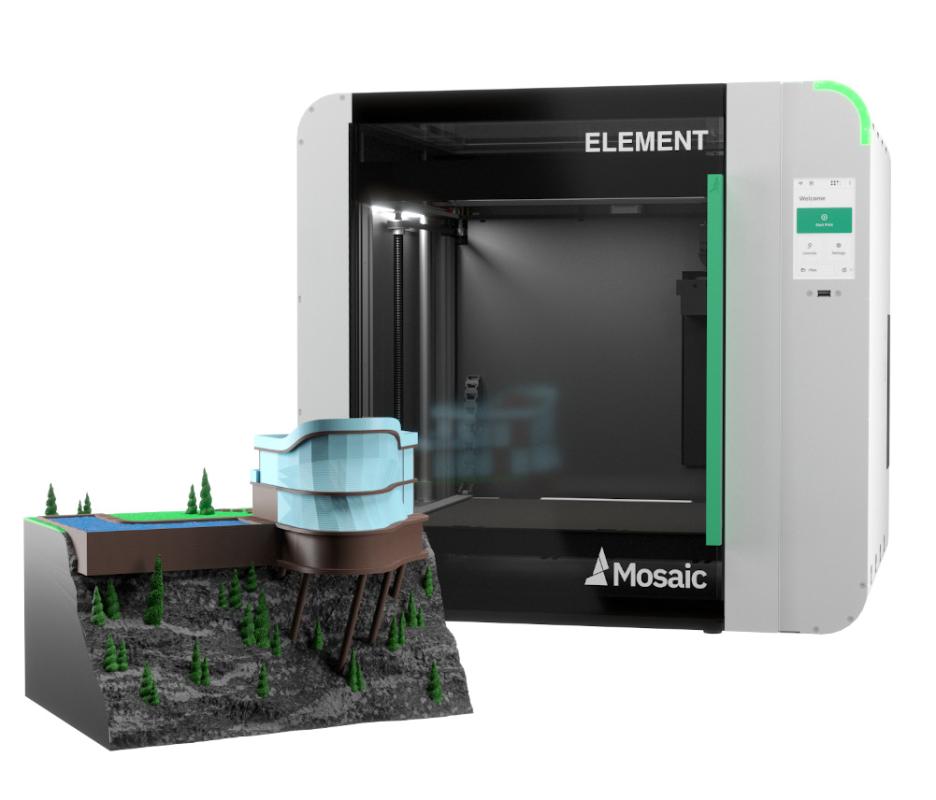

Bei BFi3D verstehen wir, dass die Anforderungen und Einsatzgebiete des 3D-Drucks je nach Branche stark variieren. Unsere Kunden stammen aus vielfältigen Bereichen wie dem Maschinenbau, Designbüros oder Bildungseinrichtungen. Wir sind uns bewusst, dass ein Maschinenbauunternehmen andere Anforderungen hat als ein Designbüro oder ein Bildungsträger.

Unsere maßgeschneiderten Schulungen reflektieren diese Vielfalt. Wir nehmen uns nicht nur die Zeit, die individuellen Bedürfnisse unserer Kunden zu verstehen, sondern gestalten auch den Schulungsinhalt entsprechend. Dabei berücksichtigen wir die spezifischen Anwendungsfälle, Herausforderungen und Ziele jeder Branche.

Ob es um die präzise Fertigung von Prototypen im Maschinenbau, kreative Designprozesse in einem Design Office oder pädagogische Aspekte in Bildungseinrichtungen geht – wir passen unsere Schulungen zeitlich und inhaltlich an, um sicherzustellen, dass unsere Kunden das maximale Nutzenpotenzial aus dem 3D-Druck ziehen können. Mit diesem individualisierten Ansatz streben wir danach, die speziellen Anforderungen jeder Branche zu erfüllen und unseren Kunden ein maßgeschneidertes Schulungserlebnis zu bieten.

Login