€2,654.70*

Available in 7 days, delivery time 1-2 weeks

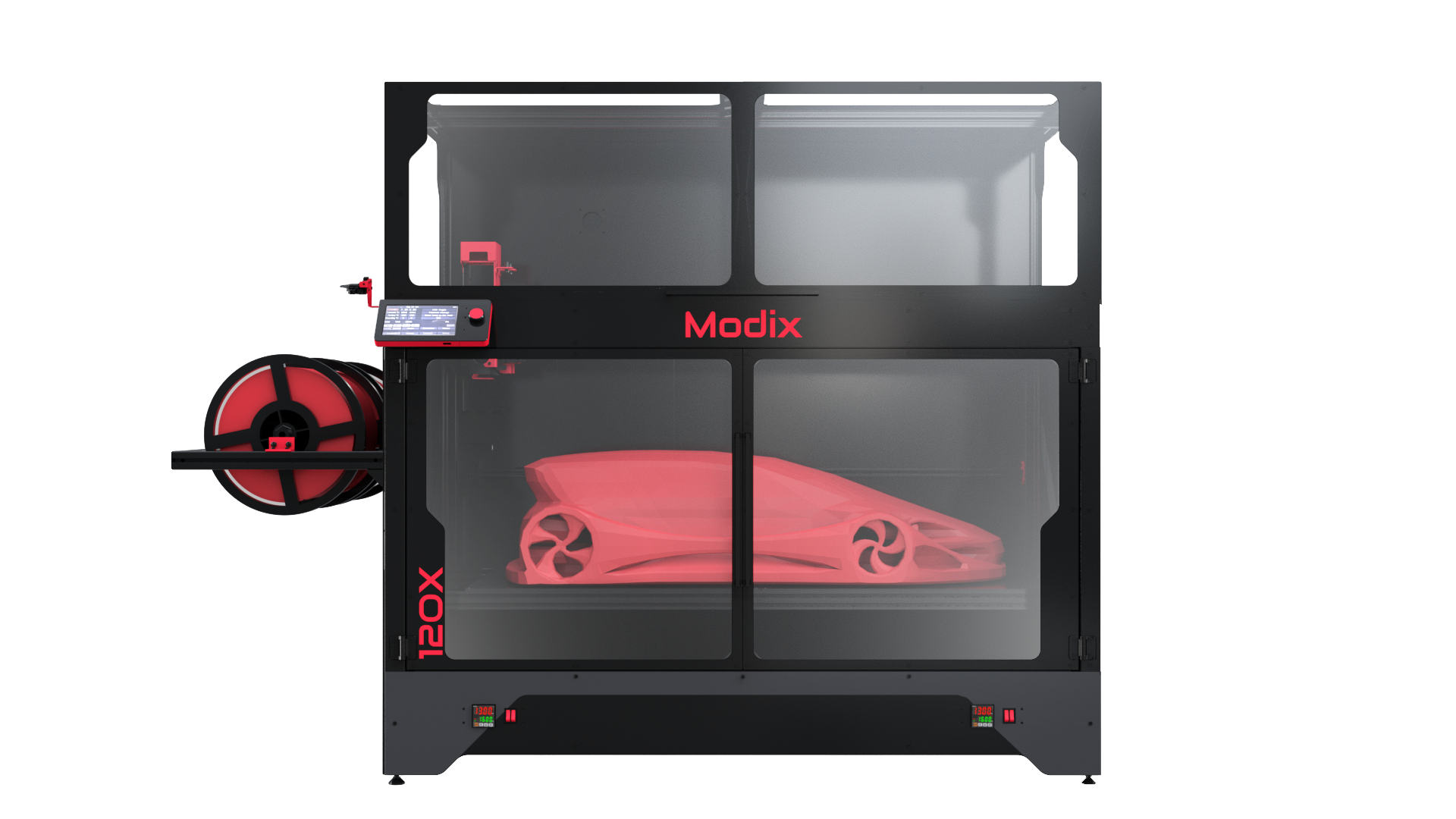

Modix upgrade from V3 to V4

This upgrade offers a groundbreaking improvement to your 3D printing experience for a number of reasons. Not only does it enable faster and more reliable printing, but it also introduces the innovative IDEX (Independent Dual Extruder) technology, which opens up completely new printing possibilities.

IDEX technology revolutionizes the printing process by idling the print head outside of the print bed. This creates an extremely clean transition between the main print filament and the support filament. This makes it easy to print complex models, including those with internal geometries, thin structures that require supports but could easily break, and models without flat bases. You save valuable post-processing time that would normally be required to remove support material. With a special filament for "easily breakable supports", this task becomes even easier. In addition, IDEX technology can be used as a filament changer without having to worry about a spool running out. This upgrade opens up new possibilities and saves time.

IDEX technology requires advanced knowledge of slicing the models, but this is covered by Modix's knowledge base. This information is published in the special customer area for IDEX users, which is password protected.

Modix places great emphasis on backwards compatibility to provide owners of previous printer models with a continuously improved printing experience. The investment in Modix large-format 3D printers will therefore retain its value in the long term.

The most important improvements at a glance:

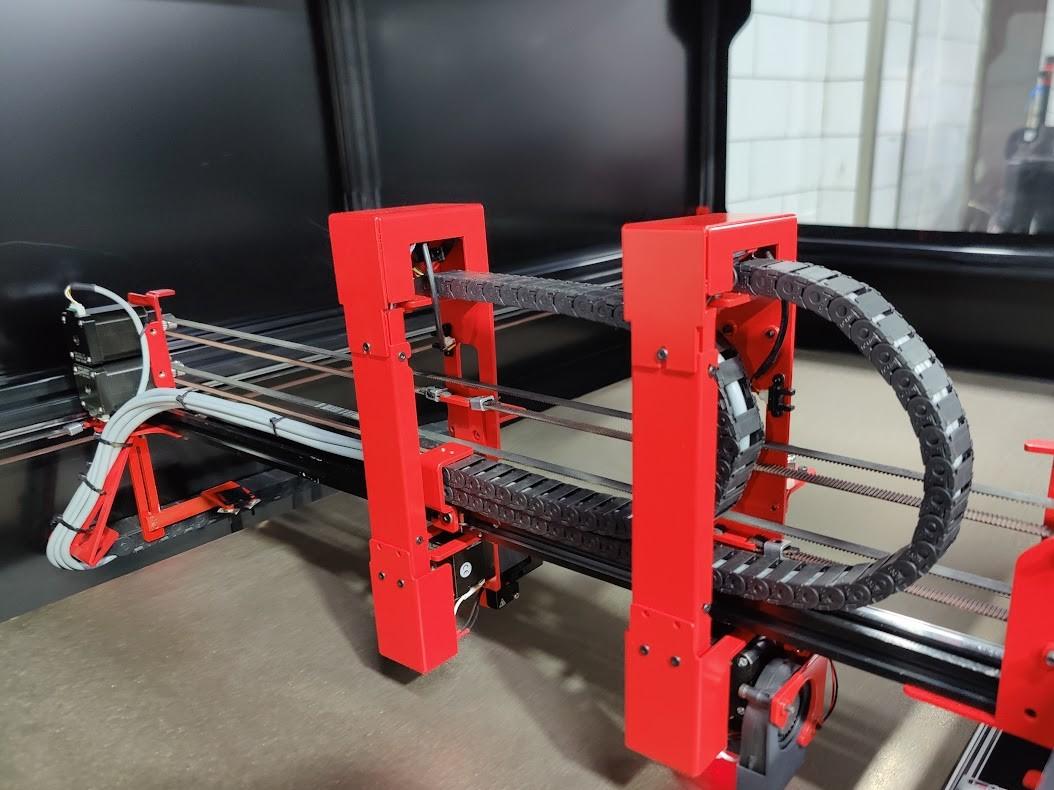

- IDEX technology: Advanced dual-material printing with independently driven extruders, resulting in cleaner print results as the print head is parked outside the print bed.

- Higher print speed: Up to 250 mm/s print speed and 350 mm/s travel for faster prints.

- Powerful motors: Powerful Nema 23 motors for the X-axis ensure fast acceleration.

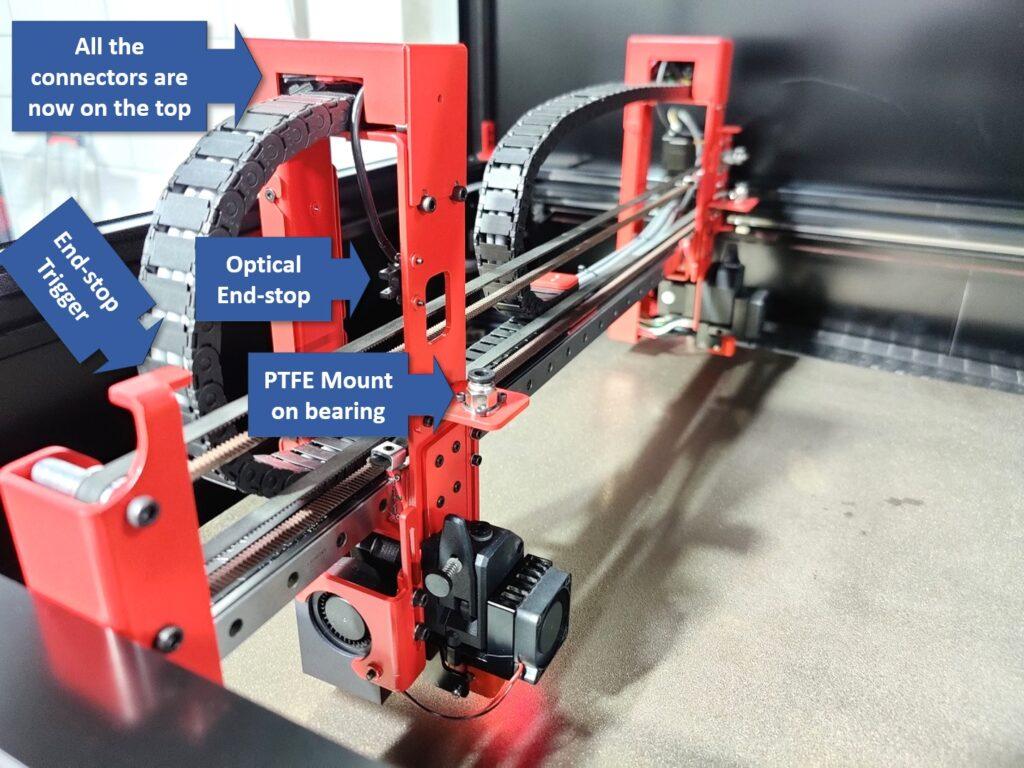

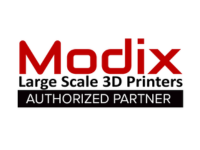

- Precise positioning and recovery: Optical end stops enable precise positioning after power failures or interruptions.

- Improved reliability: Optimizations in cabling, motor strain relief and more ensure higher reliability.

- New design: Housing improvements such as seals, hinges, pneumatic cover, rear service door and more.

- Automatic calibration: Automatic gantry calibration and bed tilt based on the DUEX expansion board.

- Modix Griffin printheads: High-flow and shock-resistant printheads for robust performance.

This upgrade takes your 3D printing experience to a new level. Order the Generation 4 upgrade today and take advantage of these impressive improvements!

Priming stations: Getting the print heads to move precisely and independently is one thing, but the real challenge is making sure they work flawlessly for days on end without clogging. Modix has developed several strategies to overcome this and other challenges associated with IDEX technology, and one of these strategies is the so-called priming stations.

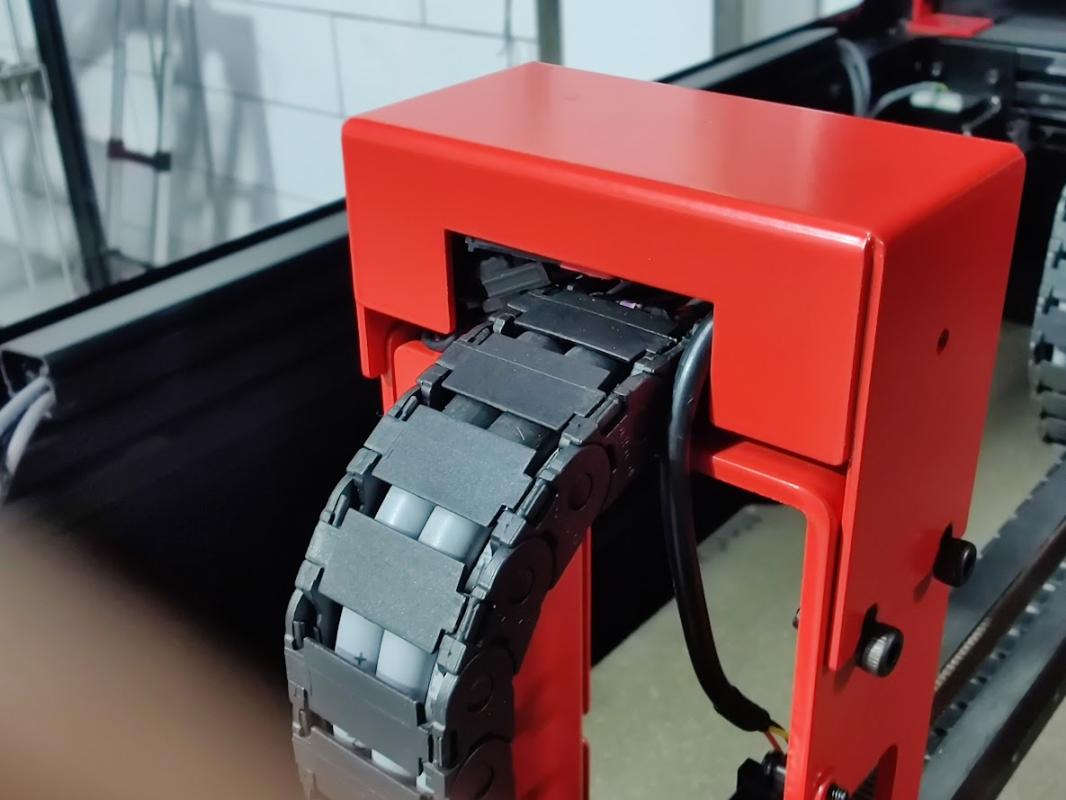

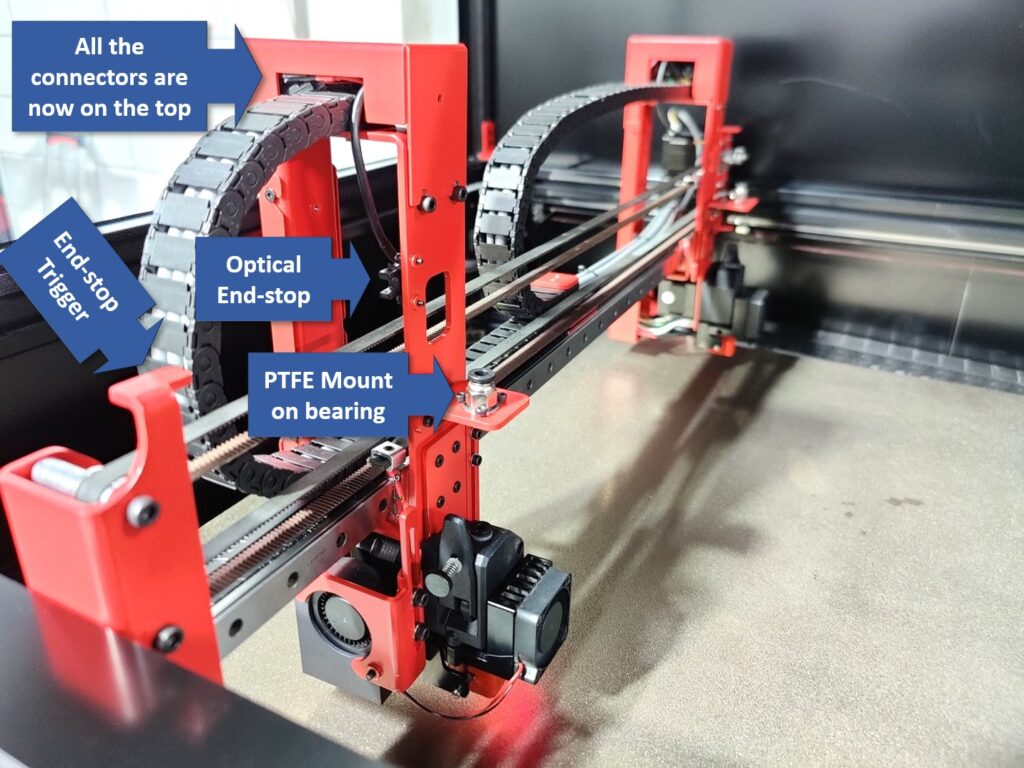

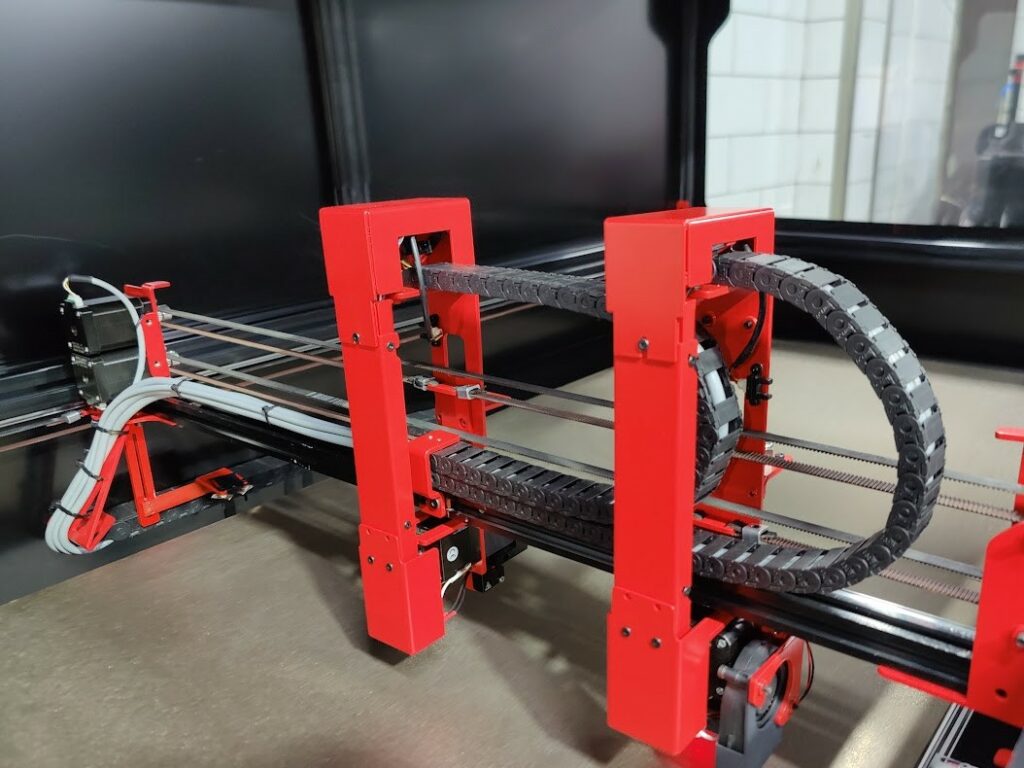

Clean cable routing: A major improvement lies in the arrangement of the cable connections. These are now located under the top cover instead of at the bottom as before. As each print head only carries its own cables, identifying the required connections is extremely easy. Two lightweight and compact drag chains keep the cables neat and space-saving by folding into each other as the printheads move.

Easy maintenance: The design includes slide-in covers that make replacing components on the printhead extremely easy. Thanks to diagonal slots, there is no need to remove screws. Rear and bottom covers are also connected and can be removed as one piece, making maintenance even easier. An upgrade to the new housing even allows access via a rear maintenance hatch designed specifically for the secondary IDEX extruder.

These improvements not only optimize performance, but also facilitate maintenance and access to the printer's components.

Filament changer: A key benefit of the IDEX system is that it uses the same type of print material, allowing seamless switching between printheads once the active printhead runs out of filament. This prevents unnecessary idle time and ensures that your 3D printer works continuously - be it during the night or at the weekend. In this way, efficiency is increased and you can rely on your printing project without having to constantly check for filament supplies. This results in improved print quality, as thin-walled print jobs no longer need to shrink during a reel change. In addition, this changer enables the complete utilization of filament spools, which would otherwise often remain unused due to their low residual quantity.

Internal geometries: The introduction of IDEX technology opens up the ability to print complex models with internal geometries that were previously not feasible due to a lack of practical options for removing the internal support structure. Previous configurations placed the two print heads next to each other, which risked drops of soluble material inside the model. This often led to defects and impaired the printing process. Thanks to IDEX, the inactive support print head is parked outside the print bed, resulting in clean and flawless print results.

Geometric freedom: Using the same materials for both the model and the support structure in IDEX prevents the support structure from bonding too strongly to the model. This is a common problem that jeopardizes thin-walled models when the support structure is removed. IDEX technology eliminates the need to unnecessarily adjust models for 3D printing just to ensure flat surfaces. The versatility of printing is extended, and models with thin features and complex shapes can also be produced with ease.

Tight tolerances: The way models with support structures are cut usually requires subdivision of the support structure. IDEX makes it possible to use support material only for these dense support layers, which reduces costs and requires less material overall. This not only leads to a more efficient use of resources, but can also reduce printing time, especially for models where printing starts well above the first layer.

Login